Overview

Due to the robust technology and the simple principle of measurement, averaging pitot tubes can be used in many different ways

even under difficult conditions and offer considerable advantages over other measuring technology from easy installation to long-term measuring stability.

Further special advantages are the possibilities of bidirectional flow measurement as well as the integration of temperature and pressure measurement.

even under difficult conditions and offer considerable advantages over other measuring technology from easy installation to long-term measuring stability.

Further special advantages are the possibilities of bidirectional flow measurement as well as the integration of temperature and pressure measurement.

Benefits

* Easy to retrofit (no rebuilding of the pipe)

* Easy to install

* Good for large nominal diameters

* Wide range of application (media, nominal diameters, process conditions)

* Minor measurement inaccuracy

* Special designs possible for special applications

* Also work in rectangular ducts and pipes

* Easy to install

* Good for large nominal diameters

* Wide range of application (media, nominal diameters, process conditions)

* Minor measurement inaccuracy

* Special designs possible for special applications

* Also work in rectangular ducts and pipes

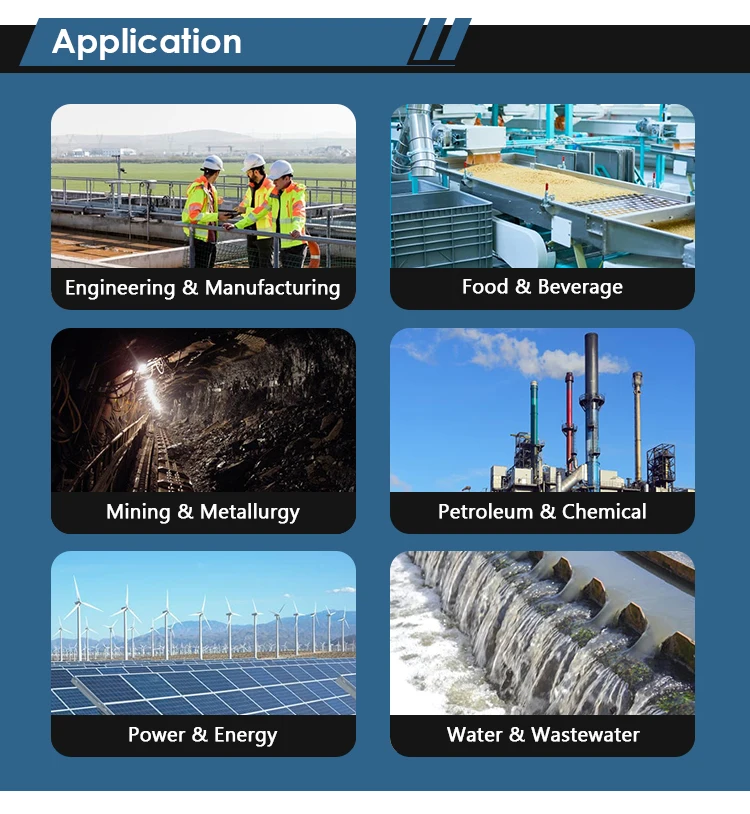

Application

* Technical Gases

* Compressed Air

* Exhaust Air

* Fresh and Combustion Air

* Heat Transfer Fluids

* Water

* Exhaust Gas

* Steam/Heat Quantities

* Compressed Air

* Exhaust Air

* Fresh and Combustion Air

* Heat Transfer Fluids

* Water

* Exhaust Gas

* Steam/Heat Quantities

Design

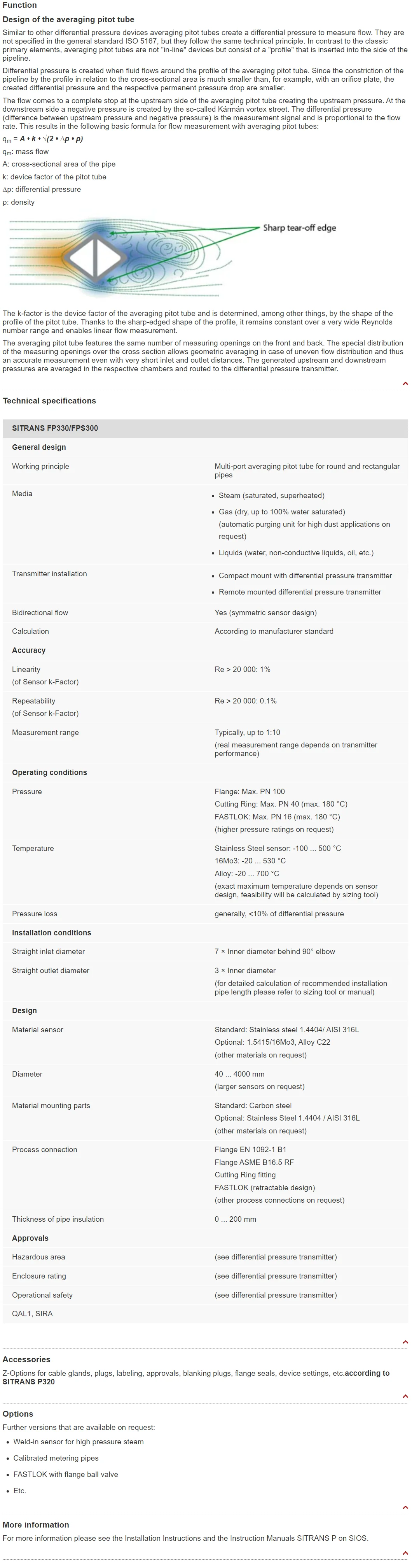

Basics: Averaging pitot tubes for flow measurement

* Mounting by insertion into the pipe (no flange-to-flange instrument)

* Differential pressure generation through forced flow

* Variation of the classic "pitot tube" through multiple metering orifices (so-called "averaging pitot tube")

* Design follows manufacturer guidelines, not standardized

Designs

* Averaging pitot tube for gases and liquids (7ME161)

* Averaging pitot tube for steam applications (7ME162)

* Averaging pitot tube with FASTLOK (7ME163), to remove sensor during operation without interruption of process

System design

* Compact design for dry gases and liquids without integrated temperature measurement

* Compact design for wet gases with or without integrated temperature measurement as well as for dry gases and liquids with integrated temperature measurement

* Compact design for steam with or without integrated temperature measurement

* Remote design for dry or wet gases, liquids and steam

* Mounting by insertion into the pipe (no flange-to-flange instrument)

* Differential pressure generation through forced flow

* Variation of the classic "pitot tube" through multiple metering orifices (so-called "averaging pitot tube")

* Design follows manufacturer guidelines, not standardized

Designs

* Averaging pitot tube for gases and liquids (7ME161)

* Averaging pitot tube for steam applications (7ME162)

* Averaging pitot tube with FASTLOK (7ME163), to remove sensor during operation without interruption of process

System design

* Compact design for dry gases and liquids without integrated temperature measurement

* Compact design for wet gases with or without integrated temperature measurement as well as for dry gases and liquids with integrated temperature measurement

* Compact design for steam with or without integrated temperature measurement

* Remote design for dry or wet gases, liquids and steam

Specification

|

item

|

value

|

|

Warranty

|

1 Year

|

|

Customized support

|

OEM

|

|

Place of Origin

|

Germany

|

|

Brand Name

|

SIEMENS

|

|

Model Number

|

FPS300/FPS330

|

|

Type

|

Differential Pressure Flowmeter

|

|

Linearity

|

RE > 20,000: 1%

|

|

Repeatability

|

RE > 20,000: 0.1%

|

|

Media

|

Steam, liquids, gas

|

|

Operating Pressure

|

up to PN100 (flange)

|

|

Operating Temperature

|

-100 °C ... 490 °C

|

|

Installation Conditions

|

Inlet: 7 x inner diameter Outlet: 3 x inner diameter

|

|

Design

|

Acc. to PED 2014/68 EU

|

|

Approvals

|

QAL1 Ex, SIL, ... acc. SITRANS P320

|

|

Material Sensor

|

Standard: Stainless steel 1.4404/ AISI 316L

|

|

Thickness Of Pipe Insulation

|

0 ... 200 mm

|

Q: How can I get the quotation or send my inquiry to?

A: Send us your inquiry via the inquiry on the right or bottom of this page.

To recommend the most suitable sensor for you, please tell us the information below.

1. working temperature: -20~+80 °C or other?

2. Test range: ?

3. Output: 4-20mA, RS485 or others?

4. Screw: G1/4, 1/4NPT, or others?

5. Electrical connection: DIN43650, Packard, Direct lead or other?

6. Order quantity: ?

7.Receiving country and region: ?

A: Send us your inquiry via the inquiry on the right or bottom of this page.

To recommend the most suitable sensor for you, please tell us the information below.

1. working temperature: -20~+80 °C or other?

2. Test range: ?

3. Output: 4-20mA, RS485 or others?

4. Screw: G1/4, 1/4NPT, or others?

5. Electrical connection: DIN43650, Packard, Direct lead or other?

6. Order quantity: ?

7.Receiving country and region: ?

please contact email for more about the shipping cost

We normally ship by DHL, UPS, FEDEX or TNT,

some country could not be ship by above method, then we would use EMS or Country Logistics line.

We normally ship by DHL, UPS, FEDEX or TNT,

some country could not be ship by above method, then we would use EMS or Country Logistics line.

English

English Arabic

Arabic

Chat with Us

Chat with Us